Conveyor belts are an important part of many industrial and commercial processes.

There are a variety of different types of conveyor belts, each with its own unique set of benefits and drawbacks.

This blog post will discuss the different types of conveyor belts and explain how they work. It will also provide some tips on choosing the right type of belt for your needs.

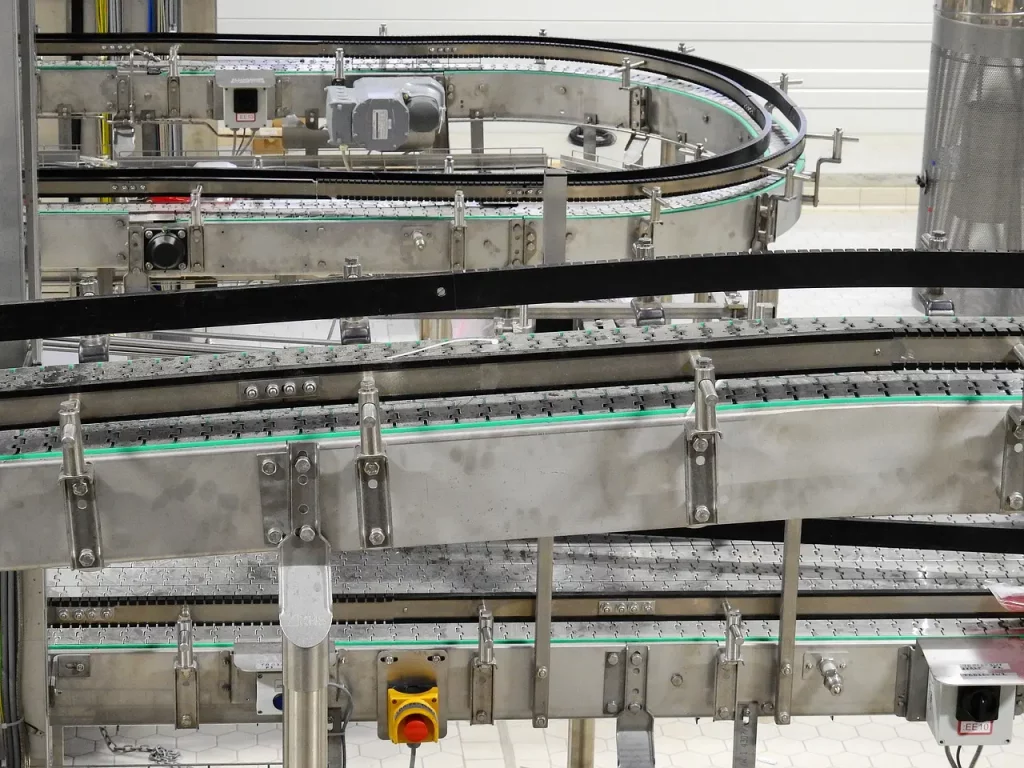

Spirals

One of the primary types of conveyor belts is the spiral belt. As its name suggests, a spiral belt consists of a series of interconnected spirals that rotate around one another.

This type of belt is typically used for transporting small items or materials that need to be spread out over a large area.

Spiral belts are also commonly used in packaging and food processing applications. A spiral conveyor will prove to be beneficial because it can gently move a product from one area to another without causing any damage.

Just keep in mind that spiral belts require a lot of space, so they are not ideal for tight or confined spaces.

Straight running

A straight running conveyor belt is the most common type of belt. It consists of a continuous loop of material that runs in a straight line. This type of belt is ideal for transporting large items or materials over long distances in manufacturing industries.

Straight running belts are also very efficient and can move a large volume of material quickly. This means that they are perfect for applications where speed is important.

However, keep in mind that straight running belts can be a bit dangerous, so they should not be used in areas where there is people or animals present.

They are also not suitable for transporting small items or materials.

For this reason, you should only use a straight running belt if you need to move large items. Otherwise, you would be better off using a spiral or curved belt.

Curved belts

A curved belt is similar to a straight running belt, except that it curves around in a circular pattern.

This type of belt is ideal for transporting small items or materials over short distances.

Curved belts are also very efficient and can move a large volume of material quickly. This means that they are perfect for applications where speed is important.

Just like a straight running belt, a curved belt can be dangerous, so it should not be used in areas where there is people or animals present.

It is also not suitable for transporting large items. Hence, it is better to only use a curved belt if you need to move small items.

Flat belt

Another type of conveyor belt is the flat belt. This belt is made from a single piece of material, usually rubber or PVC, and it has a smooth surface.

Flat belts are best used for conveying light objects over short distances. They are not very durable and can easily be damaged if they come into contact with sharp objects or heavy materials.

As much as possible, you should avoid using a flat belt in high-stress applications. This is because it is not designed to handle heavy loads.

Wedge belts

A wedge belt is a type of curved belt that has a V-shaped profile.

Just like curved belts, this type of belt is also ideal for transporting small items or materials over short distances.

Wedge belts are also very efficient and can move a large volume of material quickly. This means that they are perfect for applications where speed is important.

Just like a curved belt, wedge belts can be dangerous. Nevertheless, they are still a better option than flat belts for transporting small items.

Rollers

There are also roller conveyors which are made up of one or more rotating cylindrical rollers.

Just like a straight running conveyor belt, this type of belt is ideal for transporting heavy items over long distances. Roller conveyors are also considered to be very efficient.

Additionally, roller conveyors are not as dangerous as straight running belts, but they can still cause injuries if you are not careful.

Picking belt

A picking belt is a type of flat belt that has been specifically designed for use in picking applications. It features several small, evenly spaced bumps on its surface.

This allows it to grip onto small items securely, making it ideal for transporting delicate objects. Picking belts are also very durable and can withstand heavy loads.

However, they are not as efficient as other types of belts and can move only a smaller volume of material per hour.

Rest assured that a picking belt will get the job done, but you may want to consider using a different type of belt if speed is important.

Powered conveyors

Power is often needed to move materials on a conveyor belt.

This is where powered conveyors come into play.

A powered conveyor uses an external power source, such as an electric motor or engine, to drive the belt.

This type of conveyor is perfect for moving large or heavy items over long distances. It can also be used to move materials up and down steep slopes.

Powered conveyors are very efficient and can move a lot of material quickly. However, they are also expensive and require a lot of maintenance.

If you need to move a large volume of material quickly, then a powered conveyor is the best option for you.

Incline belt

An incline belt is a type of powered conveyor that has been specifically designed for use in inclined applications.

It features a motorized pulley that allows it to move materials up and down steep slopes. Incline belts are very efficient and can move a lot of material quickly.

They are also very reliable and can handle large loads without any problems. Incline belts are perfect for applications where you need to move materials up or down a slope efficiently.

In conclusion, there are many different types of conveyor belts available on the market. Each type has its own unique set of benefits and drawbacks. So, it is important to choose the right belt for your needs. If you are unsure which type of belt is best for you, consult a conveyor belt manufacturer or supplier. They will be able to help you select the perfect belt for your application.