In the ever-evolving landscape of industrial operations, efficiency isn’t just a buzzword—it’s the cornerstone of success. The right investments in equipment and technology can revolutionize productivity, giving businesses a much-needed edge in today’s competitive market. But what constitutes a “smart” investment? And how can you ensure that the equipment you choose will indeed boost your operation’s efficiency?

Identifying and investing in the right technologies can be a game-changer, enabling you to leverage advancements for operational excellence. These decisions are pivotal in optimizing workflows, reducing costs, and enhancing product quality.

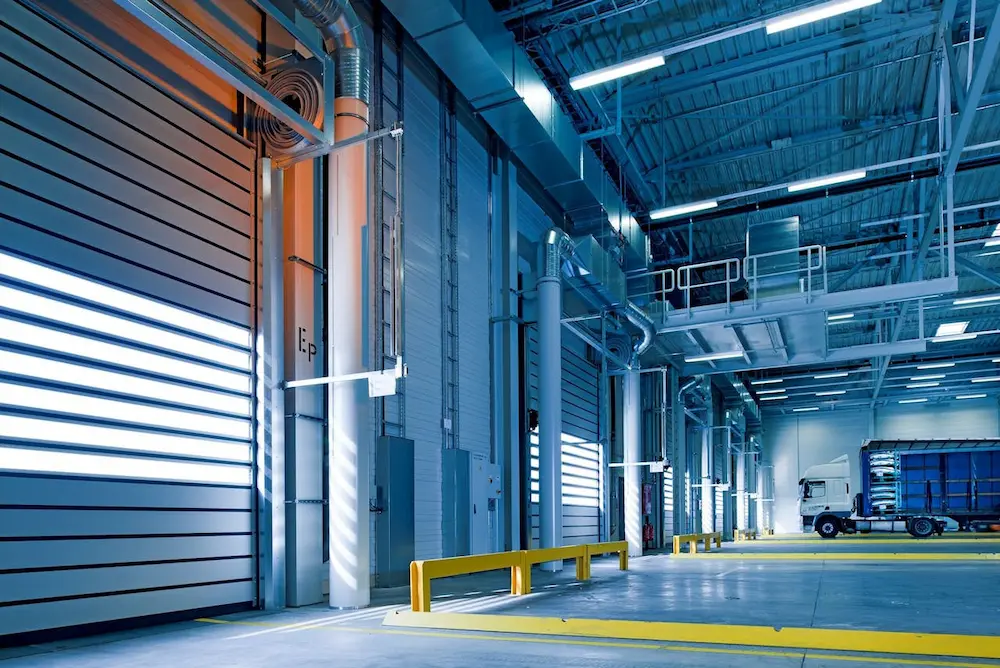

The Role of Technology in Industrial Efficiency

Technology has fundamentally transformed the industrial sector. From the assembly lines of the early 20th century to today’s automated systems, each leap forward has reshaped how we think about manufacturing, processing, and logistics. These advancements aren’t just about doing things faster; they’re about doing them smarter, with less waste, lower costs, and greater precision.

In this digital age, staying abreast of technological innovations is crucial for any business looking to maintain a competitive edge. The integration of IoT devices and AI into industrial processes has opened new avenues for optimization and efficiency. Moreover, the data collected from these technologies provides invaluable insights for continuous improvement.

Key Equipment That Enhances Efficiency

Automation Systems

At the heart of many modern industrial operations lies automation. Robotics and automated systems take over repetitive, tedious tasks, freeing human workers for complex decision-making roles. This not only increases efficiency but also reduces the potential for error, ensuring a consistently high-quality output.

Automation’s scalability means it can grow with your business, adapting to increased demands without a corresponding increase in labor costs. Furthermore, these systems often come with sophisticated software that offers real-time monitoring and control, enhancing operational transparency. Their adaptability to various tasks makes them an indispensable part of modern manufacturing and logistics operations.

Material Handling Equipment

Taking the example of space-saving low-profile hoppers, we delve into their significant role within the broader category of material handling equipment. While they may not boast the widespread recognition of their larger counterparts, the efficacy of these streamlined hoppers in operational efficiency is profound. Engineered to seamlessly integrate into spaces where conventional hoppers falter, advanced low-profile hoppers enhance material flow and optimize space usage, all while bolstering safety measures. By ensuring the smooth and efficient movement of materials, these sophisticated hoppers are instrumental in reducing downtime and refining operational processes.

Their design is particularly beneficial in facilities with limited overhead space, allowing for more efficient use of the working area. The customization options available for low-profile hoppers ensure they can be tailored to specific materials and workflow requirements, further enhancing their utility. Their ease of cleaning and maintenance also contributes to reducing operational downtime, making them a smart investment for any business looking to improve its material handling processes.

Material handling advancements extend beyond the humble hopper. Innovations in conveyor systems, for example, can dramatically speed up the movement of goods through a facility, reducing bottlenecks and improving overall workflow. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are also revolutionizing material transport within facilities, offering flexible and scalable solutions that can easily adapt to changing operational needs. These technologies not only improve efficiency but also enhance workplace safety by reducing the need for manual handling.

Energy-Efficient Machinery

As concerns about climate change and operational costs rise, the value of energy-efficient machinery has never been clearer. Equipment that uses less energy to perform the same tasks not only lowers utility bills but also contributes to a company’s sustainability goals—a growing concern for consumers and regulators alike. This shift towards greener operations is not just an ethical choice but a strategic one, as it can significantly improve a company’s market position.

By reducing the carbon footprint of your operations, you not only comply with increasing regulatory demands but also appeal to a growing segment of eco-conscious consumers. Moreover, the operational savings realized from lower energy consumption directly improve your bottom line, making energy efficiency a win-win investment. Additionally, many governments offer incentives for companies that invest in energy-efficient technologies, further reducing the cost of these investments.

Predictive Maintenance Tools

Predictive maintenance represents a significant shift from the traditional reactive approach to equipment upkeep. By using sensors and AI to predict equipment failures before they happen, companies can avoid the costly downtime and repairs that come with unexpected breakdowns. This proactive approach ensures that machinery is always operating at peak efficiency, with maintenance scheduled at the least disruptive times.

The data-driven nature of predictive maintenance not only minimizes maintenance costs but also extends the lifespan of equipment by preventing excessive wear and tear. It allows for a more targeted maintenance strategy, where resources are allocated based on actual needs rather than a predetermined schedule. The adoption of predictive maintenance is a clear indicator of an organization’s commitment to operational excellence and sustainability.

Investing Smartly in Equipment for Long-term Benefits

Making the right investment in industrial equipment requires a careful balance of upfront costs and long-term benefits. A robust cost-benefit analysis should consider not only the purchase price and expected lifespan of the equipment but also the savings in labor, energy, and maintenance costs. Additionally, scalability and flexibility are crucial.

The best equipment choices are those that can grow with your business, adapting to future challenges and opportunities. This forward-thinking approach ensures that your investments continue to pay dividends long into the future, keeping your operations agile and responsive to market changes. Furthermore, selecting equipment with a strong support and service network can minimize potential disruptions, ensuring that any issues are quickly resolved.

Training and integration are also vital components of a smart investment strategy. Even the most advanced equipment can’t deliver its full value without a workforce skilled in its operation and maintenance. Investing in training ensures that your team can make the most of new technologies, maximizing efficiency gains. This not only enhances the skill set of your workforce but also boosts morale by investing in their professional development. A well-trained team is more effective, more efficient, and more motivated, which translates into better performance across your operations.

Overcoming Challenges

Adopting new technologies and equipment comes with its share of challenges. Resistance to change is a common hurdle, as is the integration of new systems with existing processes. Overcoming these obstacles requires a clear strategy, from securing buy-in at all levels of the organization to ensuring a smooth transition with minimal disruption to operations. Open communication and involving staff in the decision-making process can help alleviate resistance to change.

Furthermore, pilot programs or phased rollouts can demonstrate the benefits of new equipment, building confidence in the investment. Additionally, choosing equipment and technologies that are compatible with existing systems can simplify integration efforts, reducing the technical challenges involved in updating your operations.

Conclusion

In the fast-paced world of industrial operations, efficiency is more than a goal—it’s a necessity. Smart investments in equipment and technology can make the difference between leading the pack and struggling to keep up. By staying informed and strategic in these investments, businesses can not only enhance their operational efficiency but also secure a sustainable, competitive advantage. As we look to the future, the ability to adapt and innovate will continue to be a key drivers of success. Now is the time to assess your operations and consider where investments in efficiency could propel your business forward.